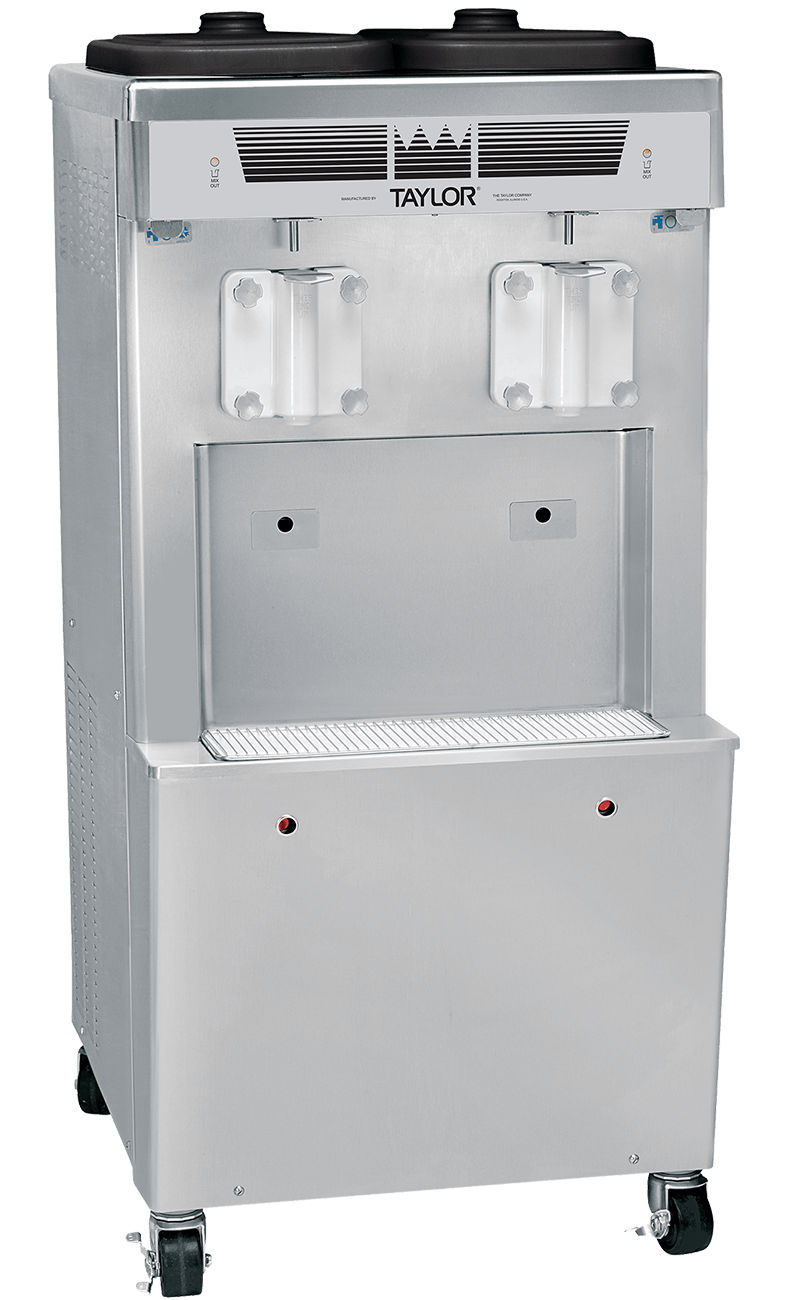

Taylor C606 Combination Shake & Soft Serve Freezer

The Taylor C606 is a high-capacity, pump-fed combination freezer designed for operators who need to serve soft serve and shakes from one reliable system. With a dedicated soft serve barrel and a shake barrel supported by four built-in syrup lines, the C606 makes it easy to offer multiple shake flavors alongside a smooth, consistent soft serve product—all from a single footprint.

Built for busy quick-service restaurants, amusement parks, and other high-traffic concepts, the C606 is engineered for fast recovery times and steady output throughout the day. Its pump-fed design delivers precise overrun control on both sides, helping maximize yield while maintaining reliable product quality. With an integrated heat treatment system that requires only 13 full cleanings per year, the C606 reduces labor, minimizes waste, and increases uptime for operations that run long hours. For teams that need dependable performance and menu flexibility without adding extra equipment, the C606 is a powerful all-in-one solution.

Features

- The Heat Treatment system provides a daily heating and cooling cycle to safely maintain dairy products up to 28 days before a complete disassembly and cleaning is required. Heat Treatment freezers address food safety, product waste, maintenance, and repair cost concerns.

- Shake Dispensing – Offers four separate shake flavors: chocolate, vanilla, strawberry, and an optional flavor. Frozen mix and syrup are automatically blended and dispensed into the cup. When the cup is filled, the portion control shuts the syrup off just before the dispensing door closes to ensure there is no flavor or color carry over.

- Shake Syrup System – Lower front compartment. Peristaltic pumps deliver the proper amount of syrup for the best flavor and consistency.

- Soft Serve Dispensing – Ergonomic draw handle with hidden adjustment screw to allow operator to set the proper draw rate. The star design pattern is integrated into the dispensing door, reducing operator replacement parts.

- Simplified air/mix pump delivers the precise amount of mix and air to the freezing cylinder for consistent overrun.

- Two Locking Front Casters – Front casters have a locking feature for operators to keep equipment in place. The lock can be released to move the equipment for cleaning.

- Microprocessor touch controls are embedded in a durable tempered glass panel. Multiple languages are selectable. Viscosity is continually measured to dispense consistent quality soft serve desserts. Temperatures in the hoppers or freezing cylinders may be displayed at any point of operation, in either Fahrenheit or Celsius. Draw counter allows operator to view number of servings dispensed.

- Syrup Rail offers four compartments for sundae toppings: two heated with syrup pumps and two room temperature with lids and ladles.

- Optional accessories include cup/cone dispenser, hopper locks, and syrup tanks.

- High capacity combination unit.

- Simplified pump (easy to clean/maintain).

- IoT Compatible.

Specifications

| Finished Product | Soft Serve, Shakes |

|---|---|

| Model Style | Floor |

| Number of Flavors | 4 Shake, 1 Soft Serve |

| Freezing Cylinder Quantity | 2 |

| Freezing Cylinder Size | Shake: 7 Quarts/6.6 Liters, Soft Serve: 3.4 Quarts/3.2 Liters |

| Hopper Quantity | 2 |

| Hopper Size | 20 Quarts/18.9 Liters |

| Mix Delivery System | Pump |

| Refrigeration Control | Electronic Viscosity |

| Dimensions | Width: 25-1/4"/641mm, Depth:38-7/8"/987mm, Height: 60-7/16"/1535mm |

| Net Weight | 815 lbs/369.7 kg |